Call: 07971891537( PIN:805)

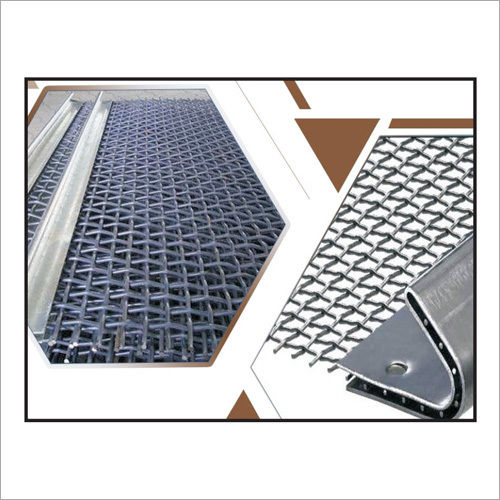

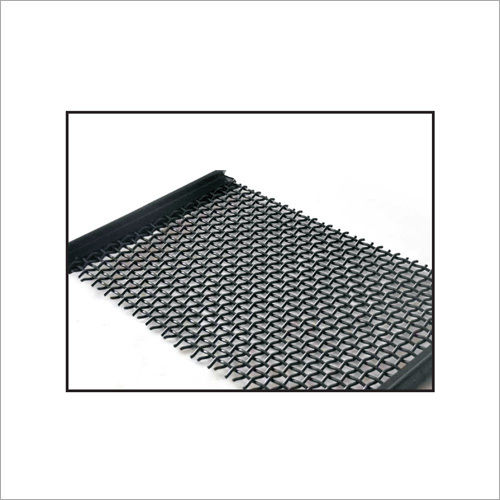

Vibrating Screen Wire Mesh

MOQ : 1 Piece

Vibrating Screen Wire Mesh Specification

- Surface Treatment

- Painted

- Product Type

- Wire Mesh

- Mesh Type

- Iron Wire Mesh

- Mesh Style

- Plain Mesh

- Material

- Iron

- Application

- Screen

- Weight

- 1 - 1000 Kilograms (kg)

- Color

- Black

Vibrating Screen Wire Mesh Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 10000 Pieces Per Month

- Delivery Time

- 3 - 6 Days

- Main Domestic Market

- All India

About Vibrating Screen Wire Mesh

Widely used for separating feeds we have come up with Vibrating Screen Wire Mesh. It helps in separating solid and crushed ores. It is double mesh and woven wire used in stone crushing units. This is a plain mesh style painted in black color. It is made with high-end iron that has multiple holes in it.

Optimized for Industrial Screening

Engineered with precision, our Vibrating Screen Wire Mesh is designed to deliver optimal performance in rigorous industrial screening tasks. Its plain mesh structure allows efficient separation while maintaining structural integrity, making it ideal for heavy-duty environments such as mining and aggregate processing.

Durable Iron Construction

Manufactured from high-quality iron, and coated with a protective black paint, our mesh provides excellent resistance to corrosion and wear. This ensures longevity and consistent performance, even in applications exposed to harsh working conditions.

FAQs of Vibrating Screen Wire Mesh:

Q: How is the Vibrating Screen Wire Mesh used in industrial screening?

A: The Vibrating Screen Wire Mesh is installed onto vibrating screens to separate, grade, or filter various materials in processes such as mining, quarrying, and aggregate production. Its iron construction and plain mesh style make it effective for sifting stones, minerals, and other granular materials.Q: What benefits does the painted surface treatment offer?

A: The painted surface treatment provides an additional layer of protection against moisture and corrosion, extending the lifespan of the wire mesh and preserving its structural integrity, even in harsh or humid environments.Q: When should I choose iron wire mesh for screening applications?

A: Iron wire mesh is most suitable when strength and cost-effectiveness are required. Select this mesh for medium to heavy-duty screening needs, especially where durability and resistance to wear are important.Q: Where is this mesh commonly used?

A: This mesh is widely used in mining, construction sites, stone crushing units, and industrial screening facilities across India. Its robust design suits a broad spectrum of screening environments.Q: What is the manufacturing process of this mesh?

A: The mesh is produced by weaving iron wires into a plain, uniform mesh pattern, followed by painting the surface for corrosion resistance. This process ensures each mesh meets precise industrial specifications.Q: How does the mesh improve operational efficiency?

A: The consistent and uniform mesh openings ensure reliable separation and grading, minimizing clogging and the need for frequent replacements. This enhances operational efficiency by maximizing throughput and reducing downtime.

More Products in Wire Mesh Category

Perforated Wire Mesh

Price 100 INR / Piece

Minimum Order Quantity : 1 Piece

Mesh Type : Iron Wire Mesh

Alloy : Yes

Mesh Style : Plain Mesh

Surface Treatment : Painted

Stone Crusher Wire Mesh

Price 90 INR / Piece

Minimum Order Quantity : 1 Piece

Mesh Type : Iron Wire Mesh

Alloy : Yes

Mesh Style : Plain Mesh

Surface Treatment : Painted

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry